CORK

CONTENTS BELOW INCLUDE:

- ADVANTAGES OF CORK FLOORS

- DURABILITY OF CORK FLOORING

- INSTALLING CORK FLOORS (INCLUDES VIDEO)

- GREAT CORK

- GENERAL CORK

- SHOWERCORK

- DYI REFINISHING

VIDEO http://www.youtube.com/watch?v=rPVcdc03Qjc&feature=related

NOTE: ANY PART OF THE GENERAL INFORMATION FOUND BELOW SHOULD NOT ASSUME TO BE OF A SOLE CAUSE OF FAILURE. PARTICULAR FAILURES SHOULD HAVE A COMPLETE EVALUATION.

- A Drunkard cannot meet a Cork

Without a Revery -

And so encountering a Fly

This January Day

Jamaicas of Rememberance stir

That send me reeling in -

The moderate drinker of Delight

Does not deserve the spring -

Of juleps, part are in the Jug

And more are in the joy -

Your connoisseur in Liquors

Consults the Bumble Bee -

This poem was written in 1882, near the end of Dickinson's life. The allusion to Jamacia evokes images of a lush and rich spring in the middle of a winter day. This idea of spring is expanded: it is a delight to be enjoyed fully, not in moderation; the joys of spring and of nature are more intoxicating than mere liquor. Like a drunkard rejoices in smelling wine on a cork, Dickinson cannot meet with the memory of spring without a "revery."

1. ADVANTAGES OF CORK FLOORS

ANOTHER GREEN FLOORING OPTION: PUT A CORK IN IT!

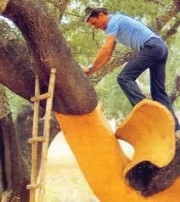

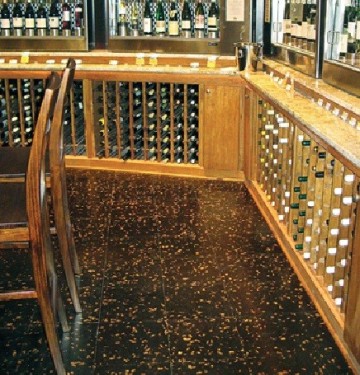

Cork is a great “green” choice for those interested in a picking a sustainable and beautiful material that avoids the health and environmental problems. No trees were killed in the process of making the beautiful floor shown at right! That’s because cork is actually the bark of a cork oak tree, genus Quercus suber. It can be stripped off of the tree every nine years or so without damaging the tree. Cork oaks live up to 200 years, and their forests — “Montados” — are treasured and have been passed down through families in the Mediterranean areas where the trees grow. Most of those forests are concentrated in Portugal, which is home to 30% of the world’s cork trees and 70% of world cork production. (The trees have been grown in California, but they haven’t produced bark with the same qualities as the European trees, which come from Spain, Algeria, Tunisia, Italy, Morocco and France, as well as Portugal.) In fact, you can feel good about choosing a cork floor, because in recent years, a flagging demand for cork — much of which was used to stopper wine bottles — has devalued the forests. As wine corks have been replaced with metal screw tops or plastic stoppers made from petroleum products, families have sold or abandoned cork forests and land, shrinking the trees’ available habitat. HARVESTING OF A CORK TREE That’s a shame, because the business of growing cork has been around for centuries. The first Portuguese regulations protecting cork trees were written by Portugal’s King Dinis in 1320, and cork floors have been used in churches and libraries since 1898, long before they were used in private homes.

CORK’S NATURAL ADVANTAGES

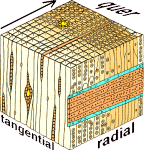

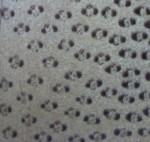

Cork contains a natural, waxy substance called suberin, which is not only waterproof, but also resists insects, mold and mildew. That’s great if you or you loved ones suffer from allergies. Suberin is fire resistant, and cork doesn’t release any toxics when it burns. Cork is pleasantly springy under foot — much kinder to your back than a cement or tile floor — and because it’s filled with little air pockets, it insulates and absorbs noise. It’s also naturally flame-resistant. Structurally, cork bark is a cellular honeycomb structure of 14-sided polyhedrons; inside they are 90% air. Those qualities make it a nice choice for a kitchen. Because cork is rather elastic, it can take foot traffic or heavy furnishings and still recover. The cork honeycomb contains about 40 million of cells per cubic centimeter, and they allow cork to be compressed up to 40% and still spring back to its original shape. That elasticity also makes cork forgiving enough to install over rather uneven surfaces. You can mount cork on top of a wood or linoleum floor, or you could also use it as an underlayment for ceramic, wood or stone.

CORK WALL TILE IN "PUMPKIN" COLOR FROM AMCORK

Cork can be purchased in rolls or in tiles, and it can be mounted on walls, as well as floors. (I’m currently eyeing some beautifully colored cork tiles for a bedroom wall. The wall is cold because it’s poorly insulated and it’s on the outside perimeter of the house. That particular wall is also showing some cracks and has old, uneven plaster, so cork tile might be just the answer.) Cork also comes in an astonishing range of colors and patterns, so it can enhance not only the tactile and audial qualities, but also play a starring role in a room’s design.

CARE, FEEDING AND LIFESPAN

Cork floors, like cork trees, can be remarkably long-lived. With fairly straightforward care, your cork floor should last for a very long time. Your cork floor will be dressed with a wax, acryllic or ceramic coating, and it’s primarily this coating that you will be maintaining. (Ceramic is the most durable of these choices and UV-cured wax is the greenest.) Here’s all you need to do:

- Vaccuum or sweep weekly

- Damp mop monthly, but don’t use a lot of water

- Use a mild soap that is PH-balanced, and make sure the surface is free of grit and sand

- Avoid abrasive cleaners and oil or ammonia-based cleaning products

Inlaid cork flooring from Globus Flooring

DOWNSIDES TO CORK

You will note that the cautions above mention both grit and abrasives, and there’s good reason for that: Cork flooring scratches! The scratches usually marr the coating on top of the cork rather than the cork itself, but it’s still a problem. Cork is soft – its Janka hardness rating is 200, harder than balsa but softer than pine. But cork is so different in character that it’s not entirely comparable. For example, cork actually has the ability to spring back and “heal” a cut so that you later can’t find it! For this reason, you should pay attention to the durability of the coating on top of the cork. The wear finish on a cork floor may either be applied at the factory or in your home, and it’s usually varnish, oil or sealer that is hardened with ultraviolet light.

Cork is not a good choice for bathrooms because it will buckle when exposed to too much water. In addition, the darker shades can be prone to fading, particularly in sunny areas.

THE FINE GREEN PRINT

The question of sustainability is always complex, and although I have extolled many of cork’s green virtues above, there is one notable drawback. The cork we buy must be shipped across the ocean, making for a large carbon footprint. Brainworks creates inlaid flooring from cork, and also combines cork with other materials such as linoleum, which is also green. The image above is cork and the one below is a combination. Click the image to visit Brainworks' gallery. The processing of cork is fairly simple. Cork sheets or pieces are cured, boiled and pressed. Scraps are collected for reuse, so almost nothing is wasted. But toxics can definitely come in to the equation! Some cork flooring is made with binders, finishes or substrates that contain carcinogens. I would avoid cork composition floors because cork is sometimes combined with Polyvinyl Chloride (PVC) to make a resilient flooring that looks like linoleum. But while linoleum is a green material, vinyl is not! The vinyl manufacturing process may hazardous byproducts and the disposal may leach toxins into the environment. (The U.S. Green Building Council has acknowledged “strong environmental and human health concerns” with vinyl.) The cheapest cork comes from China, and because it is subject to very little environmental regulation, it is likely to contain toxic glues.

INSTALLATION OF CORK FLOORS

Like pre-finished wood floors, cork floors can either be installed as “floating” floors from panels that snap together with a tongue-and-groove system, or they can be glued down. Having your floor glued down will save you on material costs, but you will pay more for labor, and it can be harder to repair a glued-down floor should you later need to do that. Some floating floors can be installed over hard surfaces — vinyl, wood or tile — but cork needs more stability that you would get from a carpet or soft floor. If you don’t have such a surface, you will need to have a contractor install a stable subfloor.

COST AND SUPPLIERS

The cost of having a cork floor installed in your home runs from $5 to $10 a square foot, with the flooring itself priced about $2.50 a square foot (2009 costs). The best quality, non-toxic versions are within that range. The European Union’s standards for toxics are 100 times stronger than those here, so one good, non-technical way to find a cork floor that doesn’t contain harmfull chemicals is to search out European flooring. An inlaid floor from Brainworks that combines cork with other eco-materials. Here are some manufacturers and suppliers whose websites you might wish to browse:

Duro Design Flooring: http://www.duro-design.com/index.cfm/cork-flooring

Wicanders: http://www.wicanders.com/en

WE Cork: http://www.wecork.com

Natural Cork: http://www.usfloorsllc.com

Globus Cork: http://www.corkfloor.com

American Cork Products (cork wall tiles as well as flooring) http://www.amcork.com

Originally utilized in many Eichler homes, natural cork flooring continues to be one of the most popular flooring options for new home owners because of its aesthetic appeal, walking comfort, good heat-transfer and retention capabilities, and easy maintenance. One disadvantage to cork is its tendency to fade over time, especially in a sun-drenched environment.

2. DURABILITY OF CORK

The Durability of cork flooring

The durability of cork flooring is something that you will never need to worry about. One of the unique characteristics of cork flooring is that it has a “memory” and recovers well from compression, very much like a wine cork.

Cork flooring has been popular for use in public buildings such as court houses, churches, banks, libraries and kindergartens. The softness and compressibility, or give, of cork reduces the jarring action in the body that occurs while walking on regular hard flooring surfaces.

The durability of cork flooring is attributed to the peculiar cellular structure of the cork. The octagonal cells are thickly packed in a honeycomb fashion. This structure allows it to absorb impacts and regain its original shape after compression. High heeled shoes and slender furniture legs can lead to denting in cork flooring. In these cases, cork flooring will regain its shape. This feature of cork is referred to as 'memory'.

There are other secrets to encourage cork to recover from dents. Simply take a towel and dampen it with hot water (microwaving the towel in a plastic bag is a good alternative to boiling a kettle of water). Place the super-heated (yet mild/moderately damp) towel over the indentation. Allow the towel to sit in place for 1-5 minutes (the deeper the indent the longer the treatment). The indent will have recovered a significant amount of its memory by the end of the treatment.

To add to the natural durability of cork products are that they are typically factory finished with three layers of water-based polyurethane (PU) varnish. Water-based polyurethane provides a clear satin finish. It is fast drying, odor free, and does not contain any Volatile Organic Compounds (VOCs).

3. CORK INSTALLATION

CORK FLOORING INSTALLATION INSTRUCTIONS

GENERAL PRECAUTIONS:

Floating Floor must be laid indoors on a clean, stable, flat, smooth and dry surface. Handle the packages carefully during transport to avoid damaging the tongues and grooves; laying damaged Floating Floor is not covered by the warranty. Store CORK Floating Floor flat for 48 hours, in open packaging, at room temperature (15°-30°C / 60°-85°F and a maximum of 75% relative humidity) in the room in which they are to be installed,

CONCRETE SUB-FLOOR PREPARATION:

1) Ensure that your sub-floor is clean, flat, smooth and level. Slopes of more than 5 mm over 2 meters or 1 /4" over 6 feet must be leveled. Correct any changes in slope using a leveling compound. After leveling, wait at least 1 week to allow the compound to dry completely before laying your CORK Floating Floor.

2) Apply a dust-inhibiting sealant.

3 Lay a moisture barrier of 0.2 mm / 0.008" polyethylene plastic and overlap any edges by 200mm / 8". Using a wide adhesive tape, seal the edges by taping along the entire seam.

4) Lay the moisture barrier up the walls 50 mm / 2", to prevent moisture from penetrating the edges of the flooring.

5) Lay the polyethylene foam or other approved underlay over the moisture barrier. Tape the edges together using the wide adhesive tape, but do not overlap.

6) Proceed to instructions on PREPARING TO INSTALL.

WOOD AND OTHER SURFACES

1) Insure that your sub-floor is clean, flat, smooth and level. Slopes of more than 5 mm over 2 meters or 1 /4" over 6 feet must be leveled. Correct any changes in slope and ensure that the leveling compound has lost Its moisture prior to starting your installation.

2) Lay the polyethylene foam or other approved underlay, taping the edges together using the wide adhesive tape, but do not overlap the edges.

3) Proceed to instructions on PREPARING TO INSTALL,

Special notes: l) On all concrete floors, the carpeting and under padding must be removed to avoid possible humidity problems. 2). For floors with radiant heating: The radiant heating system must be operational and you have to make sure to turn on your thermostat on at least 1 week prior to installation to avoid drastic variations in the floor moisture content. Turn off heat and let sub floor cool down to room temperature 3-4 hours prior to starting the job. BEFORE installation begins, ascertain that the heating system is designed and controlled for wood flooring and that the circuit does not Include other floor covering types. Failure to do so may cause excessive heat damage and shrinkage.

NOTE: Refer to radiant heat system manufacturer's precautions for nail down installation. Beware of nailing through radiant tubing or mesh, After installation, turn system back on immediately. The finished floor surface must not exceed 29°C (85° F) throughout the life of the floor. Radiant heating systems normally create dry heat that can lower interior humidity levels. It may be necessary to add humidity with humidifiers to maintain the recommended levels (35-55%) and prevent damage to the wood floor. Following the installation you should maintain the room temperature below 26 °C (80°F).

PREPARING TO INSTALL:

1) Let the opened packages of flooring lie flat on the floor for at least 48 hours prior to installation, in the room in which

the floor is to be installed.

2) Make sure to leave a clearance of at least 12.5 mm / 1 IT between the top surface of the HOME LEGEND CORK

flooring and the underside of baseboard heaters.

3) Check door and doorframe clearances to insure that doors will move freely without contacting the cork surface.

4) Remove existing moldings and baseboards,

5) Clean and sweep.

6) Although a HOME LEGEND CORK Floating Floor can be installed in any direction, as a rule, Floating Floors are usually installed perpendicular to a wall with a window, Installing the Floating Floor parallel to the longest wall tends to make a room appear larger. CORK is a natural product individual planks will vary in color and design, You will get better results by laying two or three rows of Floating Floor in advance to get an eye pleasing distribution of the plank colors and patterns.

INSTALLATION:

CORK flooring is designed for glue-less laying and must be laid as a "floating floor".

1) Measure the room carefully to determine if it is square, and to calculate the width of the last row. For planks less than 50 mm / 2" in width, re-cutting the first row will be necessary to insure stability (do not include the tongue of a plank in your measurements, as all exposed tongues must be removed from the perimeter of the floor, i.e. the first row of planks). Should you have an irregular wall for the first row, the plank must be cut to follow the wall's irregularities. Please note that any installation requiring the flooring to exceed 8 meters / 27 feet in width or length, will require an expansion or T molding.

2) When preparing to saw a plank (use safety glasses), always insure that the teeth of the saw will be cutting into the decorative surface of the plank. (Ex: using a table saw face laminate side down).

3) Starting in one corner of the room, the flooring should be installed from left to right, with the groove sides facing out from the walls. Place spacers between the plank and the wall, 1 spacer on the width and one spacer at each end where one plank joins another. (Spacers provide the necessary space required for expansion around the perimeter of the floor. It is especially important to leave at least 8 mm / 5/16" free around the entire floor, including under doorframes). The planks at the end of each row must not be shorter than 300 mm /12", to insure stability. If your last

plank is shorter than 300 mm / 12", it is advised to re-cut the first plank in the row. The remainder of the plank from your first row can be used as the first plank of the next row. Stagger the planks by cutting the first plank of every other row in half. The pattern will then be repeated until the opposite wall is reached.

4) When laying the planks for the first row, place the first plank flat and against the spacers. The next plank being laid must be elevated at a slight angle to allow the tongue to slip into the groove of the first plank. Once flat, push and gently tap the planks together until they "clip" in tight.

5) For the second and consecutive rows, elevate the plank on the long side at a slight angle to allow the tongue to slip into the groove. The next plank should be laid the same way but, with the tongue on the left side of the plank falling just next to the previous plank. Once flat, you can push and gently tap the planks together until they "clip" in tight.

6) When you reach the final row, place a loose panel precisely on the last laid panel. Place another panel on top, but with its edge 8 mm / 5/16" from the wail. Trace a cutting line along the middle panel, and saw it along that line.

7) Lay the panel you cut and ease it into position. Insert spacers between the wall and the last panel laid to be sure there is an 8 mm / 5/16" expansion gap,

8) To pass obstacles through the floor covering (pipes, radiator mounts), use a pencil to trace the position for drilling. Find the centre then drill, using a big enough bit to leave 8 mm / 5/16" peripheral play. Cut the strip in two so that the saw mark goes through the centre of the drilled hole, so that the strip can be re-assembled around the pipe. If the obstacle is on the long side of a strip, cut it in a trapezoid shape, otherwise a straight cut would be best.

9) When going from one room to the other make sure to separate the rooms with a transition molding. The floor is ready for use as soon as it is laid.

FINISHING:

1) Remove the spacers.

2) Cover the expansion joints around the perimeter of the floor with baseboard moldings and/or quarter rounds. If a vapor barrier was used, do not forget to fold the polyethylene film along the edge of the walls under the baseboards and/or quarter rounds. Fit these products to the walls without attaching them to the floor.

3) Install the t-moldings to hide the expansion gaps where needed (doorways, more than 8 meters / 27 feet, etc.).

4) Any remaining panels can be kept for several years, stored flat in a moisture-free area, Furniture can be put back in position right away.

SEALING:

Cork has to be sealed with A WATER BASED polyurethane to protect the joints against dirt accumulation and water spillage, Bonna Kemi Taffic polyurethane or Dura Seal X-terra are good selections. Other products with comparable properties can be used. Apply two coats for light residential and 3 coats for heavy residential or commercial applications. Follow sealant manufacturer's instructions.

MAINTENANCE:

Clean the finished floor with a broom or a vacuum cleaner or with a cloth moistened with a small amount of diluted cleaning product, Stubborn stains should be removed using a cloth with a small quantity of acetone. It is recommended to use felt pads under chairs, tables or any objects that could scratch the flooring in any way.

CORK FLOORING

The Cork Oak Tree is never chopped down or destroyed, but rather the cork bark is harvested. Cork bark can be harvested approximately every 9 years. Cork is a Renewable, or Harvested resource., .never damaging the tree from which the cork is removed.

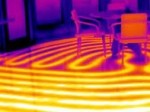

Sound & Vibration Reduction Cork reduces the transmission of sound, vibration, heat and thus is a great insulator. The tiny cellular compartments seal air in each compartment insulating each from the other with a moisture resistant, waxy-like substance, Cork reduces impact sound (IIC) as well as sound transmission (STC).

Thermal Insulation _

Cork reduces heat loss in rooms and even body heat loss through the feet. Cork naturally maintains a comfortable median temperature, never getting very hot or very cool. Walk barefoot on a cork floor and the warmth is immediately apparent. Cork is a natural thermal insulator because of the encapsulated cells containing mostly air. Anti-Allergenic and Insect Resistant Bugs, mold, mites and even termites are repelled by cork due to a naturally occurring substance in cork called Suberin. Suberin, which is a waxy substance, also prevents cork from rotting even when completely submerged under water for long periods of time.

Elasticity

Cork cell membranes are very flexible allowing cork to be both compressible and elastic. When cork is subjected to pressure or heavy weights, the air in the cells is compressed. An example would be when a cork stopper is pressed into a bottle opening. Once the pressure is released (or in the example, the cork is removed from the bottle), cork returns to its original shape. In cork flooring, this means that although its possible to make

a dent in cork with a heavy object or high-heeled shoes, the cork will recover to its original shape, unlike hardwood floors.

Fire Resistant

The natural waxy substance Suberin makes cork a natural fire inhibitor. Cork is fire resistant and also does not release any toxic gases on combustion.

Limited Residential Wear Warranty

CORK FLOORING is typically warranted to be free from manufacturing defects. Should a defect occur, Natural CORK will arrange a credit based on the original purchase of the product. This warranty is not transferable by the purchaser of the floor.

Warranty Coverage: Upon determination of a valid manufacturing defect, credit will be issued to the dealer and will be good towards the purchase of a replacement, Credit applies to material only and does not include labor since it is the responsibility of the installer to determine suitability of material prior to installation. Should a problem attributed as a manufacturing defect develop after flooring is installed, the cost of labor for repair will be covered by this warranty.

CORK FLOORING Limited Residential Wear Warranty does not typically cover:

1 . Problems due to moisture, mildew, alkaline substances, hydrostatic pressure, expansion and contraction between planks/tiles, or humidity levels above or below those recommended.

2. Damage due to scratches, gouges, scuffs, punctures, cuts, indentations, burns, accidents, lack of proper furniture rests or any intentional misuse of the product. Loss of finish gloss over time is consistent with normal wear & tear and is not a product flaw.

3. it is normal and expected for there to be color variations due to use of natural components, exposure to UV light and/or sunlight, and age of material. Therefore, color inconsistency between samples, replacement product or illustrations and actual product is not a manufacturing flaw.

4. Manufacturer makes no guarantee that the material purchased will match or coordinate with customer furnishings, trim, cabinetry, railings, etc.

5. Inherent variations that are consistent with those of a natural cork product to include pattern, color, and grain do not indicate defective material.

6. Noncompliance with installation instructions and maintenance guidelines as recommended. Manufacturer cannot assume responsibility for the suitability of flooring material and accompanying products for each individual installation as manufacturer has no control over the installer's proper application. Should an individual piece be doubtful as to appearance or dimension the installer should not use this piece. Failure to apply

protective coating in accordance with manufacturer's guidelines may result in irreparable damage to the cork. Such damage is not covered.

7. Cracking, warping, soiling, fading, improper maintenance or abuse caused by items such as roller skates, golf shoes or pets.

http://www.calibamboo.com/cork-flooring-installation-video.html

4. GREAT CORK

Know These 10 Facts for a Great Cork Job By Don Jewell

Cork flooring has been around for many years, but it’s seeing a resurgence due to its unique aesthetics and unparalled green story. Keep these 10 facts in mind if you’re working with cork for the first time.

1) Cork is not a structural product. If you’re installing 3/16- or 5/16-inch cork tiles or planks, the structure needs to come from the substrate. If it’s plywood, you’ll need at least 1 inch of plywood down before installing the cork. Directly adhering to concrete slabs and/or Portland-based level compounds is the most common method for commercial (and some residential) applications.

2) Inconsistencies in the substrate translate to the surface. Installing cork is like installing resilient flooring—the substrate needs to be free of any imperfections or they will show in the floor’s surface. If the subfloor is plywood, it must be underlayment-grade plywood and it cannot have any voids. Lots of people try to use luan, but luan can dent easily, which will transfer to the cork’s surface. OSB and particleboard also are not acceptable. It is important to follow manufacturers’ requirements; if you deviate from recommended substrates, you void the warranty.

3) The subfloor can never be too clean. Those who are used to installing hardwood floors should think about getting the subfloor as clean as they would want to get a wood floor before they put on their last finish coat. A good rule of thumb is, “The substrate can’t be too smooth, too flat or too clean.” Imperfections might not show up immediately, but once the light changes or the floor is exposed to normal traffic, they may appear.

4) You must follow the instructions for the adhesive. Most cork manufacturers only recommend a low- or zero-VOC contact adhesive. This adhesive is applied to both the back of the tile and the substrate. When these two adhesive films make “contact” with each other, they create a very strong bond. When putting the tiles in place, the adhesive will grab, so be careful to put it down exactly where you want it to go—you will not be able to push or slide a tile into place. Once placed, use a soft-faced rubber mallet to hit the entire tile surface to ensure the two films become one.

5) Know if it’s homogeneous or veneer cork. Know what construction you have before you do any abrading or finishing. Homogeneous (where the color/pattern goes through the product) is preferred for medium to heavy commercial installations, as it can be sanded. Veneer cork patterns can be screened but cannot be sanded. It is important to maintain the finish coats on both homogeneous and veneer cork.

6) Don’t be too aggressive when sanding. Lots of people use multi-head sanders to resand a cork floor, and they work well. You can also use a big machine, but you need soft drum tension and nothing coarser than a 120 belt. If you’re sanding a newly installed unfinished cork floor, you can just use a buffer and a 120 or 150 screen.

7) Many finishes work, but check with the cork manufacturer. Every cork manufacturer has specific recommendations for approved finishes on their cork. While it is possible that finishes other than their approved finish may work, the manufacturer will not support a warranty with an unapproved finish. Recommended finishes are primarily water-based urethanes; however, wax and natural oil systems are also sometimes used.

8) Maintenance is the same. You should maintain a cork floor exactly like you would a wood floor. If you wouldn’t do it on wood, don’t do it on cork.

9) Go vertical. These products are also popular for walls. The installation is the same—with contact adhesive rolled on. Many times wall installations use a wax finish.

10) When in doubt, call the manufacturer first. Manufacturers welcome phone calls for clarification of instructions and procedures prior to installations, not after.

5. GENERAL CORK

Cork Flooring

by Christi Graham

What is it?

Most of us don't notice it when we're walking on it, but cork flooring has been naturally enriching interiors for over 100 years in notable buildings such as schools, hospitals, churches, museums, libraries and hotels. It's warm honey-toned appearance, comfort underfoot and ability to soften acoustics often goes unnoticed by those of us who would not otherwise recognize it.

So what is cork? Cork is actually the outer bark of a tree, Quercus suber, which grows in the Mediterranean. Cork oak forests cover approximately 5.4 million acres amongst the seven primary cork producing countries; (30% Portugal, 21% in Algeria, 20% in Spain, 16% in Morocco, 5% in France and 4% each in Italy and Tunisia). Cork forests are carefully managed and treasured in particular by Portugal, which produces 50% of the worlds cork supply.

Cork bark is typically harvested every nine or ten years. After the slabs of cork bark are harvested they are cleaned, boiled and stripped of the rough outer surface. Bottle stopper "corks" are then punched from the best material in the slabs. The remaining scraps are then ground into small granules, mixed with a binder, molded into large blocks and baked in specialized ovens - making use of every scrap of cork bark.

Corks remarkable properties are derived from its cellular structure of hollow, polyhedral (14 sided) cells with extremely strong yet flexible cell walls that are waterproof and airtight. Joined together in a honeycomb like fashion, cork cells produce a very low-density, compressible insulating material. As a floor covering, cork is durable, provides acoustical and thermal insulation, cushions the foot, is resistant to moisture damage and decay and is easy to clean. In addition to all of these features cork is harvested from trees in a sustainable manner - making it very worthy of consideration for use in green building.

Natural cork flooring materials, which we are referring to, are quite different from the widely marketed cork-vinyl composite floor tile. Cork-vinyl products have a polyvinyl chloride (PVC) backing, a cork inner layer and a vinyl surface layer. Due to significant health and environmental concerns with PVC, natural cork flooring is preferred over vinyl.

Uses

Cork can be used as a flooring surface, an underlayment for flooring, on walls and ceilings, and is one of the main ingredients in natural linoleum. Cork has been formed into baseboards and moldings as well. In residential applications cork is successfully used in living rooms, kitchens, bathrooms and hallways.

Attributes

Health

The process of agglomerating the cork requires binders to hold the ground cork granules together. Urea formaldehyde binder was used in the past, (phased out during the 1980's) and today, urea melamine, phenol formaldehyde and natural proteins are more commonly used. Once processed, these are relatively stable binders.

Standard adhesives and finishes are a potential for introducing more volatile organic compounds (VOC's) into the air. It is recommended that you select low or non toxic products for these purposes.

Cork does not offgas or shed microfibers and is naturally moisture, mold, and rot resistant

Environmental

Corks impact on the environment is quite low due to the sustainable harvesting practices and almost zero waste from the manufacturing process. Producing nations regulate how frequently cork can be harvested in order to minimize damage to the trees. The trees survive the debarking process although they are more susceptible to injury until the protective bark is regenerated.

Functional Characteristics

Features

Most manufacturers offer cork tile in shades of light, medium, and dark, but there will always be shade variation from tile to tile.

Cork is generally available in rolls for underlayment or tiles for floor covering. Tiles are also available as floating floors and include both pre-finished and un-finished parquet tiles. Tiles are available in 12" x 12" x 3/16" and 12" x 24".

For floating floors one manufacturer, Natural Cork, LLC supplies their tiles with a pre-coated contact adhesive. his Natural Cork Floating Floor system is comprised of one by three foot planks consisting of three layers. The surface layer is 100% cork with a UV cured acrylic finish which contains no VOC's. Precut tongue and grooves of the middle layer of MDF form the interlocking layer while the base layer of cork underlayment provides significant acoustical insulation. This brand of floating floors are entirely free of PVC. Available from factories in many patterns and colors, tiles can also be stained for a unique custom color appearance.

Natural cork underlayment is supplied in rolls and sheets for use as acoustic insulation in the installation of hardwood and laminated flooring. Cork underlayment provides over 50db of sound reduction, meeting and often exceeding code requirements.

Installation

As the color varies, to achieve best results, shuffle the shade variation prior to installation.

Laying the tile - Natural cork tiles are installed by flooring professionals using adhesives. Most cork tile manufacturers recommend water-based adhesives for this task, which should be fairly stable (without offgassing) after it is cured. However, these adhesives could release potentially dangerous VOC's during installation. Dodge-Regupol, a manufacturer of natural cork, recommends Dri-Tac Flooring Adhesive, which is a water based low VOC, latex adhesive.

Applying the finish - Most cork tiles will require a protective coating. You can finish the floors with either wax or polyurethane sealants. If you choose wax, you can use any paste wax that is recommended for wood floors, however we recommend using a natural wax that has a beeswax base or has low VOC's. For a polyurethane finish 3-4 coats may be required to obtain the finish you desire. Be certain to find a water-based polyurethane finish with low VOC's.

It is recommended by one manufacturer that you do not start the finishing process for at least 5 days after installation. A light sanding may be necessary if you have any uneven areas - these can be corrected by light sanding with No. 80 mesh disc sander (3M) or equivalent.

Maintenance

Routine maintenance is a function of the finish applied.

Waxed finish - Clean with dry or damp mop, occasionally using liquid solvent wax. For a more serious cleaning on standard cork tile, use electric buffing with 00 steel wool discs then apply lamb's wool pads.

Polyurethane finish - Clean with dry or damp mop. To refinish the polyurethane tiles use power floor machine with wool disc (00 grade) and apply polyurethane as directed on container labels.

Performance / Durability

Cork is highly abrasion resistant on it's own and treating it with a protective finish further increases its durability. Cork has a tremendous amount of "memory" and recovers well from compression. Cork floors will last as long as most hardwood floors.

Considerations

If anyone in your family has a sensitivity to formaldehyde, you might consider sealing your floor with a non toxic sealant that minimizes the "off gassing". (Are there any that are made without formaldehyde?)

Who Makes It

Dodge Cork Tiles - by Dodge-Regupol, Inc.

All Natural Cork Floating Floor and Parquet Tiles - by Natural Cork, Ltd Company

Prontokorq - by Korq, Inc.is a tongue in groove floating cork flooring product that comes in 3/8" x 12" x 36" planks. Cork floor tiles measure 3/16" x 12" x 12". Both products are prefinished with a water-based varnish. Korq also offers baseboard and molding products made from agglomerated cork.

Notes

Just like any other flooring material, cork can be punctured by sharp objects and damaged by furniture feet. Protective pads under furniture are recommended.

If installing cork flooring in a bathroom take additional measures, such as caulking the perimeter of the room prior to installing baseboard, to avoid moisture penetration.

6. SHOWER CORK

Showercork is yet another new cork flooring option that uses recycled cork material to create a rich mosaic tile. Sustainable Flooring uses post-industrial wine stoppers, cuts them into thin rounds and sets them onto a special backing material, which can easily be installed much like traditional mosaic tile sheets using glue and grout. A water-based polyurethane coating can then applied for water-resistance.

7. DYI REFINISHING

DO IT YOURSELF REFINISH Instructions

- Remove any baseboards around the floor, carefully using a pry bar. Number the back of each piece with a pencil to indicate its position in the room.

- Sand the floors with an electric floor sander fitted with a 60-grit sanding pad. Cork flooring is extremely soft, so keep the floor sander moving to prevent damage.

- Load the floor sander with a 100-grit sanding pad and sand the floors again. It's important to make sure the cork surface is smooth, but limit the sanding as much as possible to prevent damage.

- Vacuum the floor to remove all sanding dust and debris. Remove any remaining residue with a tack cloth. Get the floor as clean as possible to ensure a smooth finish.

- Apply the polyurethane finish using a 4-inch exterior soft-bristled paintbrush. Start from the side farthest from the door and work your way toward the exit. Overlap your passes, working from wet to dry to minimize brush strokes.

- Allow the polyurethane to dry at least 12 hours, or according to the manufacturer's recommendations.

- Sand the finish as lightly as possible, using an electric floor sander fitted with a 00-grade wool pad, to remove any imperfections. Clean the floor with a tack cloth.

- Apply a second coat of polyurethane with the 4-inch brush. Allow the finish to dry. Apply additional coats of polyurethane, allowing each coat to dry thoroughly before applying the next, until you have achieved your desired finish.

- Reinstall the baseboards with finishing nails and a hammer.